Understanding POH: The Power Behind HDBaseT Technology

August 4, 2016 / General, Standard and Certification, Industrial Networks

Last month we posted a blog about HDBaseT that explained the application and how testing isn't really any different since standards-based Category 5e, 5 or 6A will support it. But maybe you've also heard about power over HDBaseT, or POH, and you're wondering how that differs from power over Ethernet (PoE).

A Little Bit More

Based on and backwards compa tible with the IEEE 802.3at PoE Plus standard, POH delivers up to 100W of DC power over four pairs of Ethernet cable in conjunction with video signals to a distance of up to 100 meters (m) -- enough to power a typical LED TV. In fact, Energy Star™ 6.1 restricts all TVs 60 inches or less to no more than 100W and that wattage is dropping.

tible with the IEEE 802.3at PoE Plus standard, POH delivers up to 100W of DC power over four pairs of Ethernet cable in conjunction with video signals to a distance of up to 100 meters (m) -- enough to power a typical LED TV. In fact, Energy Star™ 6.1 restricts all TVs 60 inches or less to no more than 100W and that wattage is dropping.

POH technology opens the door for a cost-effective, easy way to deliver power to digital signage in airports, hotels, hospitals, cafeterias or any other environment in need of a video display--eliminating the need for AC power. This is especially appealing for applications near water where AC power presents a safety hazard. As you can imagine, customers across every market are therefore starting to demand POH.

One key difference compared to PoE is that instead of the powered device assuming worst-case cabling, POH allows the device itself to identify the cable length and draw more power as long as it does not exceed the 100W. That's pretty much where the difference ends (other than the capital "O" in the acronym).

The Same Concerns

Like IEEE 802.at, POH comes with the same concerns inherent when running higher DC power over all four pairs--heat rise in cable bundles being one of the biggest. Because temperature is directly related to insertion loss, it's important to ensure that cable temperatures do not exceed the maximum operating temperature of 60°C specified by TIA standards and the recommended maximum temperature rise of 15°C for remote power applications.

To help combat temperature rise, it is recommended to reduce cable bundle sizes, use higher category or shielded cabling or reduce the channel length when delivering DC power. For example, a bundle of 60 Category 6A cables will exhibit about 12% less heat rise than Category 6. And shielded cable will perform even better due to the shield that acts as an insulator. Depending on the application, it may make sense to choose better performing cable to avoid having to derate the channel length down from 100 meters.

Balance Still Matters

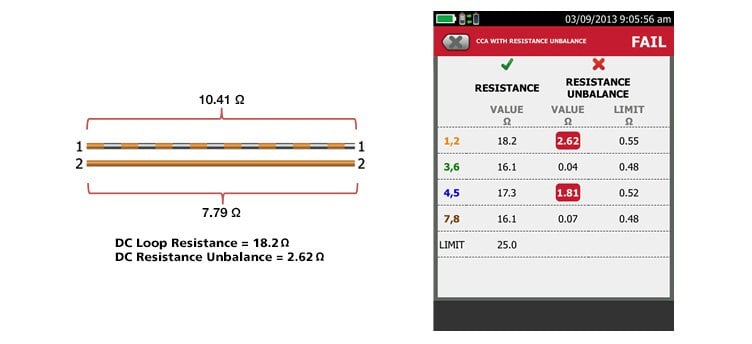

Speaking of cable choice... Do you remember how DC resistance unbalance in a PoE connection can distort Ethernet data signals? Well the same holds true for POH. But instead of bit errors and retransmits, DC resistance unbalance in a POH connection can distort the picture.

And just like in PoE connections, poor workmanship and a lack of cable quality can make it difficult to achieve the common-mode voltage that allows current to be evenly split between conductors. Even manufacturers of HDBaseT equipment warn against the impact of inexpensive, non-compliant cables like copper coated aluminum (CCA) that exhibit variations in the diameter, concentricity and smoothness of conductors and therefore have a higher risk for unbalance.

Thankfully, just like the DSX-5000 CableAnalyzer is used to test cable performance in an HDBaseT application, its ability to test for DC resistance and resistance unbalance can verify that both conductors in a pair can effectively support POH (and PoE).

If the difference is DC resistance between two conductors is greater than the maximum allowed 3% as specified by IEEE Std 802.3, there's a pretty good chance that your POH application won't be picture perfect.