What are all those specialty cords you use?

2020 年 5 月 7 日 / General, Installation and testing, Industrial Networks, Best Practices

I was recently asked by a customer, to whom I was demonstrating a Fluke Networks OptiFiber® Pro OTDR and CertiFiber® Pro OLTS, why do you need all those specialty test leads to make measurements? Why can’t I use patch cords? We often take the understanding of such things for granted, so let’s take an in-depth look at the various accessory cords you need to make measurements accurately with our testers.

Launch and Tail Cables

With the OptiFiber Pro OTDR, like the majority of OTDRs, you need a way of measuring the connector at the start of the link under test. The receive electronics of an OTDR are very sensitive, the photodiodes used must be able to detect minute amounts of light reflected after the OTDR has output its measurement pulse(s). The initial burst of light from the measurement pulse overloads the OTDR detector and it takes time for the electronics to recover. That time to recover equates to a distance the light will have travelled down the fiber. To measure your first connector (event) correctly we use what is known as a Launch Cord, this ensures that the OTDR detector will be able to “see” our first connector and measure its performance correctly. Good OTDR measurement practice also requires the use of a similar cord connected to the last connection of the fiber link under test. We often refer to this cord as the Tail Cord, it is usually the same length as the Launch Cord and helps us in correctly measuring the performance of the last connector. What if your fiber is broken at the last connector? Without a Tail Cord you will never be able to detect this problem, if you utilize a 100m tail cord, you know you must see 100m of fiber after the last connector. If you don’t see that 100m of fiber, your break is at the last connector. Plus, if you are performing bi-directionally averaged measurements on your fiber, you must use a Tail Cord to do this correctly.

Loopback and Sacrificial Cords

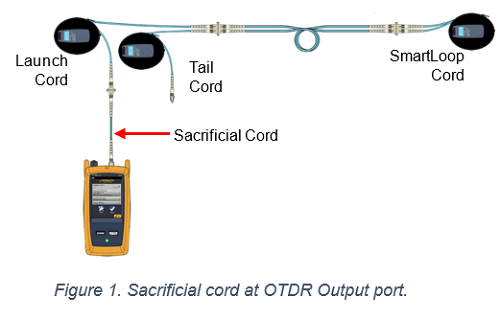

In my OptiFiber Pro OTDR demonstration, I was showing the customer our SmartLoop® OTDR measurement method that allows the OTDR to measure two fibers bi-directionally and provide an averaged result, without having to move the OTDR to the far end of the link. I was using a short, 30 cm jumper cord (often called a “sacrificial” cord) with a bulkhead adapter connected between the OTDR output port and the Launch / Tail Cords. The customer was concerned that the extra 30cm of cord would affect the OTDR measurements and wanted to understand why I was using the sacrificial cord. In the first instance, because of the OTDR Event Dead Zone (which all OTDRs have), the OTDR would never see the short sacrificial cord, it is “invisible”. The most important reason for using the sacrificial cord is to protect the OTDR output port from damage. When you are using SmartLoop OTDR mode, you need to be able to swap the launch and tail cords into the OTDR measurement output pulse path. Rather than connecting and reconnecting directly into the OTDR output port, and risking OTDR output port damage due to accidental dirt contamination, it is easier to use the sacrificial cord and just swap the end of the sacrificial cord to the correct Launch /Tail Cord, as in Figure 1. When it wears out, just replace the cord. Some customers leave a sacrificial cord connected to their OTDR for all measurements to avoid contaminating or damaging their OTDR measurement port. (Cleaning a port is relatively easy, see: https://www.flukenetworks.com/support/knowledge-base/optifiber-pror/making-sure-optifiberr-pro-output-ports-are-clean)

It should be noted at all Launch, Tail and sacrificial cords supplied by Fluke Networks use reference grade quality connectors to ensure very low loss when used correctly.

Test Reference Cords for Accurate Loss Measurements

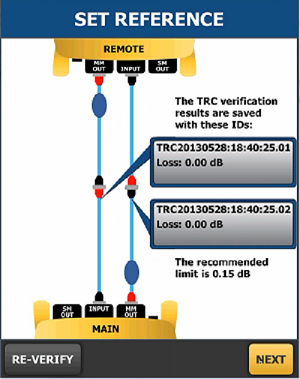

Finally, while demonstrating the CertiFiber Pro OLTS, the customer wanted to know why I was using Test Reference Cords (TRCs) to make the measurements rather than common old patch cords. To put it simply, patch cords have too much variability and loss to be able to make consistent and accurate loss measurements. TRCs use reference grade fiber and reference grade connectors so that their losses are small, <0.1dB for MM cords and <0.2dB for SM cords. They add negligible losses to the measurement, whereas standard patch cords could add as much as 0.5dB to the measurement for MM and up to 1.0dB for SM patch cords.

Finally, while demonstrating the CertiFiber Pro OLTS, the customer wanted to know why I was using Test Reference Cords (TRCs) to make the measurements rather than common old patch cords. To put it simply, patch cords have too much variability and loss to be able to make consistent and accurate loss measurements. TRCs use reference grade fiber and reference grade connectors so that their losses are small, <0.1dB for MM cords and <0.2dB for SM cords. They add negligible losses to the measurement, whereas standard patch cords could add as much as 0.5dB to the measurement for MM and up to 1.0dB for SM patch cords. Click here for more ⇒